Westeria Air Density Separation Range

Back to all News ArticlesLondon, United Kingdom

20th November 2019

0 comments

Westeria Air Density Separation Range

Other

Separating differing types of material within a waste stream can be a challenging task which often requires cutting edge machinery. Windsifters from Wisteria can provide a solution. These rugged, energy-efficient machines separate heavy and light materials using a three-part process;

Separating differing types of material within a waste stream can be a challenging task which often requires cutting edge machinery.

Windsifters from Wisteria can provide a solution. These rugged, energy-efficient machines separate heavy and light materials using a three-part process:

1. Acceleration Belt – input material enters the machine on a conveyor belt where it is spread out into a single layer. When inside the machine the conveyor belt accelerates the material to the discharge edge.

2. Air Jet – An air jet with an adjustable nozzle, located below and slightly behind the discharge belt produces an air stream that takes light materials upwards and forwards from the discharge edge to a rotational drum. The rotating drum carries the light material over the top and in to a holding chamber or are extracted via conveyor

3. Heavies Discharge Conveyor – Any heavy materials, too dense for the air stream to carry to the rotating separation drum simply fall straight down from the discharge edge and are extracted from the windsifter via a discharge conveyor

The Westeria Air Density Seperation range have applications in:

• Construction rubble

• Unsorted construction waste

• Residual waste

• Glass

• Wood

• Compost

• Commercial Waste

• Scrap Metal

• Waste Incineration Slag

• Production of refuse-derived fuel

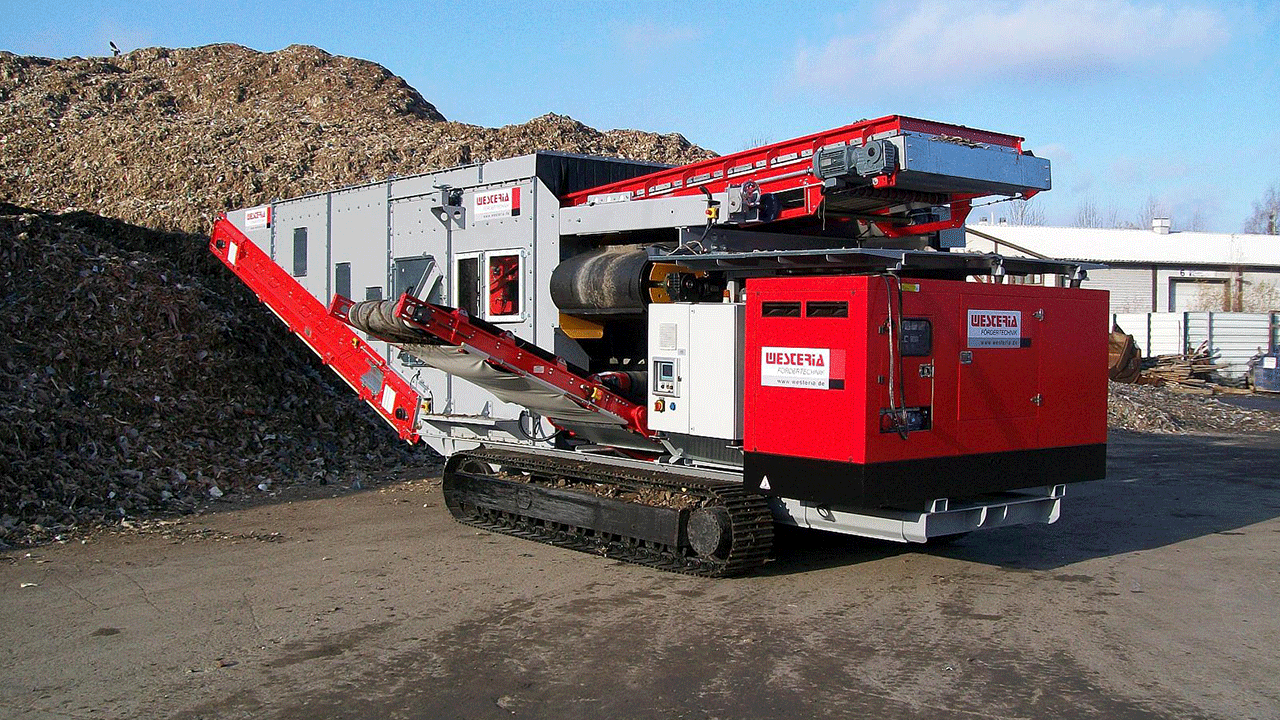

Airstar

Westeria’s air density separator contains proven technology with patented Westeria solutions. It is highly efficient due to the optimised flow design which can be adapted by the user. The Airstar can be used in circulating air operation which produces very little exhaust fumes. Available as a semi-mobile unit, wheel-mobile, caterpillar mobile or stationary unit.

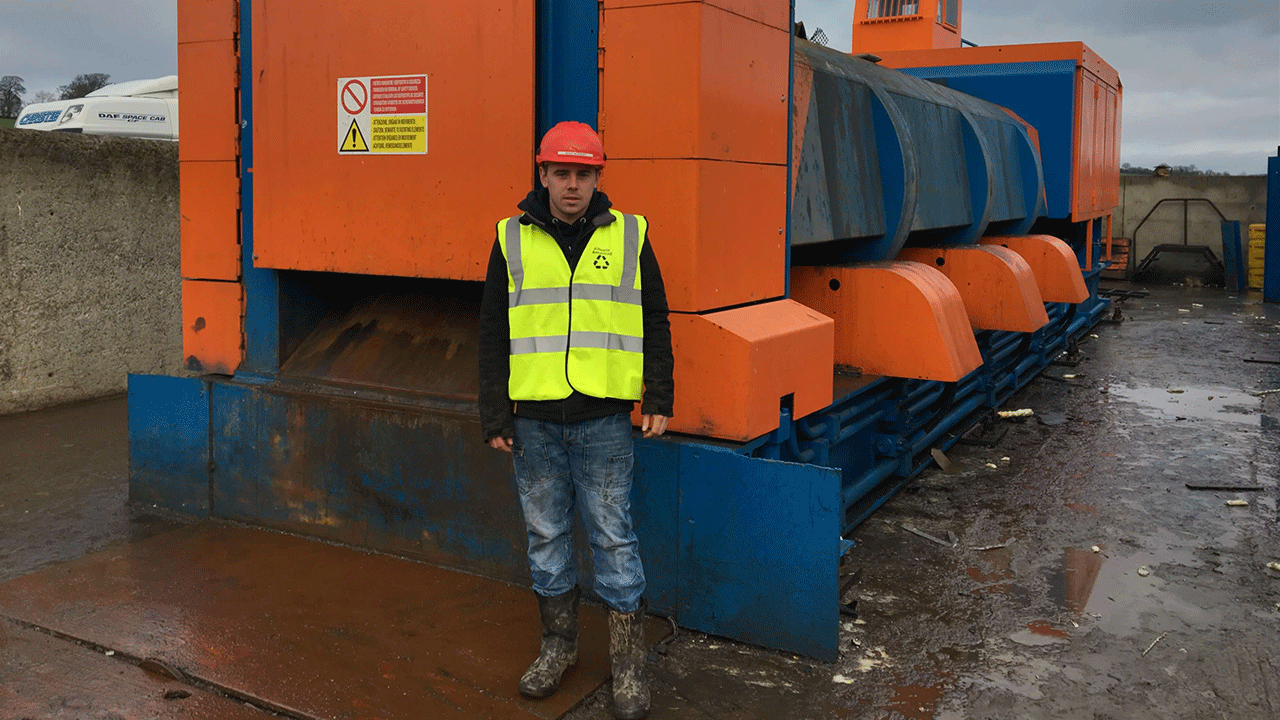

AirBasic

A simple, sturdy setting for the air separator feeder belt via cable winches means no fixed jacks. The AirBasic is equipped with an integrated air hose for cleaning and a separator drum with optional Hardox design. Pipe supports allow the AirBasic to be mechanically adjusted for height.

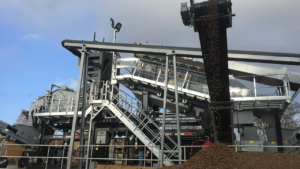

Airtrack 1

This design is the only mobile separation unit with a 2000mm conveyor width. The construction optimises weight distribution and benefits from easy loading, and low bed trailers. It requires minimal cleaning due to the hinged filter grills. The Airtrack 1 boasts impressive processing capabilities of up to 220m3/h.

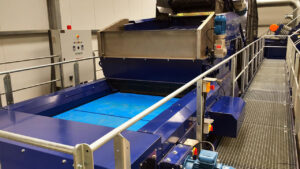

Airtrack 2

With optimal dimensions the Airtrack 2 can be used for nearly all sites and applications. Its high-performance electromagnet, providing a clean and efficient iron separation, is also guaranteed.

Operator and environmental safety is adhered to by the low-level dust emissions thanks to the sophisticated air-circulation system.

For more information on Westeria’s Air Density Separation range visit the blue-group.com website.

News

Strategic Restructuring at Blue Machinery (Scotland) Ltd

As part of a team restructuring, Blue Machinery (Scotland) Limited have announced several strategic...

Find Out More

Blue Scotland expand into Concrete Batching Plants

Blue Machinery (Scotland) Ltd are delighted to announce that they are now the authorised...

Find Out More

Take a look at the latest deals available at Blue Spares!

RECIEVE A £100 AMAZON VOUCHER WITH EVERY TROMMEL DRUM PRUCHASE Looking for a new drum for your...

Find Out More

Take a look at the latest deals available at Blue Spares!

FREE £50 VOUCHER WITH ANY SET OF MANGANESE PURCHASED Purchase any set of jaw plates, concave...

Find Out More

Blue Machinery (Scotland) announce strategic investment in Pro-Arb Machinery

Blue Machinery (Scotland) Limited are delighted to announce that they have completed a majority...

Find Out More

Blue Friday Deals!

We are running a number of deals in the lead up to Blue Friday! Here is a list of what we have...

Find Out More

Blue Southern appointed as Hidromek Dealer

Blue Machinery (Southern) Ltd is delighted to announce their appointment as the Hidromek dealer for...

Find Out More

0% finance available on new Powerscreen machines

Crush your interest rates! Subsidised rates available from as low as 0% on selected Powerscreen...

Find Out More

WE’RE GIVING AWAY A FREE RAMMER HAMMER

WE'RE GIVING AWAY A RAMMER HAMMER! Enter here: https://bit.ly/3VolJ5T As you may have seen...

Find Out More

MEGA MAY GIVEAWAY

Throughout May we are running four promotions to give you the chance to get your hands on some FREE...

Find Out More

Record breaking Con-Expo/ Con-Agg Trade Show

Con-Expo/Con-Agg 2023 drew in a record breaking 139,000 visitors to the Las Vegas event, making it...

Find Out More

Doosan to become DEVELON!

Hyundai Doosan Infracore (HDI) have today announced their new brand name. DEVELON will replace...

Find Out More

Blue Machinery become distributor for VTN attachments

We are delighted to announce that Blue Machinery and Murray Plant (A Blue Scotland Company) have...

Find Out More

Blue Machinery appointed as new dealers for Morbark

We are delighted to announce that Blue Machinery have been appointed as the exclusive distributors...

Find Out More

Blue Machinery expand Terex Washing Systems agreement across the UK

We are delighted to announce that both Blue Machinery (Southern) and Blue Machinery (Central) will...

Find Out More

Celebrating 30 years of Blue Machinery Central

Celebrating 30 Years of Blue Machinery Central 2022 is the year that we celebrate 30 years of...

Find Out More

The latest edition of Bluemail is out now! Read it here.

The latest issue of Bluemail is out now! 📖 Read it...

Find Out More

Blue Scotland to become the MDS (A Terex Brand) Distributor in Scotland & North East England

Blue Machinery (Scotland) Ltd have been appointed as the MDS distributor for Scotland and the North...

Find Out More

A Restructuring of Murray Plant for Attachment Sales

Since Blue Group purchased Murray Plant back in 2019, it has always been our goal to grow the...

Find Out More

Develon Genuine Parts – Blue Central authorised Develon Parts provider for the North West & North Wales

Blue Central stock an extensive range of genuine Develon Parts at their Develon Parts Centre in...

Find Out More

The Winter Edition of Bluemail is out now… Read it here!

Some of the highlights include: ☑️ Blue Central appointed Doosan Infracore...

Find Out More

Blue Central Appointed Doosan Dealer for North West & North Wales!

Blue Machinery (Central) Ltd are delighted to announce that they have been appointed the Doosan...

Find Out More

Blue Central Appointed New MDS – A Terex Brand Dealer

Blue Machinery (Central) Ltd have been appointed as the MDS distributor in northern and central...

Find Out More

The November Edition of BlueMail is out now. Read it here!

The November edition features some great stories including: ☑️ RFS Works...

Find Out More

Blue Exhibit at Let’s Recycle Live/Demo Expo and CARS/ MRE

September saw the return of trade shows and exhibitions within our industries, and we were...

Find Out More

The latest BlueMail is out now. Read it here!

The June 2021 Q2 BlueMail Issue is out! For this edition we've given the magazine a bit of a...

Find Out More

Blue Central take their aftermarket services to the next level with the launch of Blue Care

Coming into effect as of March 1st 2021, Blue Machinery Central has introduced three new aftersales...

Find Out More

Blue complete the design & installation of a state-of-the-art MRF for Willshee’s

Blue Machinery Central are proud to announce the completion of a new state-of-the-art MRF...

Find Out More

Take advantage of the Super Deduction with Blue!

During last week’s 2021 budget update Rishi Sunak announced ‘The Super Deduction’, which...

Find Out More

Blue Group Ranked 31st in The Sunday Times International Tracked 200

We are delighted to announce that we have been ranked 31st in The Sunday Times International...

Find Out More

Blue Spares 2020 Business Review & Colleague Awards

Blue Spares recently held their annual business review and colleague awards for 2020, albeit this...

Find Out More

Blue Southern to supply multi-million-pound waste processing facility

Blue Machinery (Southern) Ltd has been named as preferred supplier for the multi-million-pound...

Find Out More

Support to Buy Initiative 2020 – Complete this short Survey and we’ll make a donation to Age UK!

Three Questions... …is all it takes to complete our survey - and we’ll make a donation to Age...

Find Out More

Blue Group COVID-19 UPDATE

Extra Steps we're taking... Following the ongoing development of Coronavirus, we would like to...

Find Out More

Blue Spares COVID-19 Update

We wanted to update you on steps we are taking to keep our team members and business partners safe,...

Find Out More

Blue Launch 2020 offer on Fuchs Material Handlers

Introducing Blue’s new 2020 offer on the Fuchs MHL 310F and 320F Material Handlers! This limited...

Find Out More

Blue Spares employee receives staff recognition award for going the extra mile

John Dennan, Senior Account Manager at Blue Spares, went above and beyond to help a desperate...

Find Out More

Expansion of Murray Plant continues with a new Depot and the appointment of an Operations Manager

Murray Plant, A Blue Group Company, continue their expansion plans with the opening of a Warrington...

Find Out More

Murray Plant named as Shearcore’s Worldwide Distributor of the Year 2019

Superior, WI—ShearCore announced that Murray Plant, a Blue Group company, has been named the...

Find Out More

Finance Director of the Year 2019 – Susan Shardlow

On Thursday 21st November 2019, Blue attended the ‘Finance Director of the Year’ awards, at the...

Find Out More

Murray Plant appointed exclusive dealer for the UK

Murray Plant Ltd, a Blue Machinery Group company, has recently been appointed ALLU’s exclusive...

Find Out More

New Powerscreens Help Cut Asphalt Production Costs

Four Powerscreen Chieftain 1400 Screens have been purchased by KKB Group from Blue Machinery...

Find Out More

How Technology can improve recycling plants

Technology is already involved in existing recycling processes to increase speed and efficiency....

Find Out More

Why You Should Choose Genuine Crusher Spares

In order for our Blue Spares department to be as successful as it is, we rely heavily on the...

Find Out More

Blue Group appoints three General Managers within three of our divisions

Blue Group is delighted to announce the appointment of Ian Webber, Stuart Hardiman and Iain...

Find Out More

Blue Scotland Hold Successful Open Day

Blue Scotland recently held a highly successful Open Day in association with Central Demolition...

Find Out More

Blue to exhibit at Waste’17

Blue are delighted to be exhibiting at Waste’17 which is to be held on Thursday 8th June at Old...

Find Out More

Blue Finance Offer 0% for 12 Months

Get 0% for 12 months on any hire purchase, leasing or refinancing agreement until the end of May...

Find Out More

Operator Training by Blue Group

In order to continually support our customers, Blue Group have been running a number of Operator...

Find Out More

Enablelink’s SPALECK Screen Deck producing quality scrap metal

Enablelink Ltd, a well-known metal merchants formed in 2007 by Roy Millard, has just taken delivery...

Find Out More

Spares in focus

In 2014 the Blue Group made the decision to form a new Spares Division with the intention of...

Find Out More

Blue Group Appoint Adrian Murphy as CEO

We are delighted to announce the appointment of Adrian Murphy as Group CEO. Working closely with...

Find Out More

Blue Ireland announce distribution agreement with Rotobec

The relationship means that Blue will supply a range of heavy-duty attachments, used in scrap,...

Find Out More

Blue Group’s Brexit Policy Statement

In order to best be prepared for the forthcoming events relating to the Brexit scheduled departure...

Find Out More

Blue Group is thrilled to announce that we are now a member of RoSPA

As a company, Blue Machinery Group is committed to the safety of its workforce and as of December...

Find Out More

Fortress bites in the city

After a comprehensive evaluation of products, renowned Birmingham based NFDC demolition company...

Find Out More

Blue Group Appoint Susan Shardlow

Blue Group are delighted to announce the appointment of Susan Shardlow as Chief Financial...

Find Out More

Shortts Purchase First Taurus Baler from Blue

Shortts Recycling, a family run business with a long heritage in scrap metal recycling, have been...

Find Out More

Plastic Seashores: The Importance of Recycling Plastics

With the rise in single use plastics increasing dramatically every year, an immense strain has been...

Find Out More

Blue Group sign distribution agreement with CK International

Blue Group have announced a new distribution agreement with CK International, a leading...

Find Out More

Westeria Air Density Separation Range

Separating differing types of material within a waste stream can be a challenging task which often...

Find Out More

FUCHS MHL 350F

The Terex Fuchs MHL 350F is one of the most advanced machines in its class. Its state of the art...

Find Out More

Decoding the Enigma of Plastic Codes

Plastic has become the most used material in our everyday lives. Going without it takes a huge...

Find Out More

The Future of Robotic Waste Separation Technology

Technological advances in the world of waste material processing have made major strides recently,...

Find Out More

Blue Sponsored Pro Am Gets Award Nomination

A record-breaking Pro-Am golf event has been shortlisted for a major award for its contribution to...

Find Out More

Powerscreen Parts Promise

Blue Spares are delighted to introduce the Powerscreen Parts Promise offering guaranteed same day...

Find Out More

Waring Waste purchase BlueMAC All Metal Separator

When looking for a machine to help with separating ferrous and non-ferrous material from the wood,...

Find Out More

Blue Group to hold Open Day at Armac Demolition in Solihull

Blue Group will be holding a Waste Recycling Open Day on Wednesday July 12th and Thursday July 13th...

Find Out More

Blue London Announce Open Day

Blue London will be holding an Open Day on Saturday 24th June at their facility in Guildford,...

Find Out More

Danny Morgan to become Sales Director at Blue London

Blue Group are delighted to announce the appointment of Danny Morgan as Sales Director of the...

Find Out More

Opening Times Christmas and New Year 2016/17

Our Group offices close at differing times for Christmas. Blue Spares will remain open until...

Find Out More

Blue 0% Finance Offer

Blue are delighted to announce that we will be running a 0% finance offer through the month of...

Find Out More

Blue Ireland deliver Taurus Shear Baler into Molloy Metals

Molloy Metals Ltd was established in 1994 by John Molloy when he purchased a mobile car crusher,...

Find Out More

Industries That Benefit From Balers

We recently announced the distribution agreement with CK International, a company leading the way...

Find Out More

The Powerscreen Premiertrak 300/R300

Designed to exceed the primary crushing needs of customers in the mining, quarrying, and recycling...

Find Out More

Food Waste Processing: The Cesaro Tiger HS 640

With the increasing demand for landfill space across the UK, more and more is being done to divert...

Find Out More

Features within the Doppstadt DW series

The DW slow speed shredder series is a powerful range of shredders used across a number of...

Find Out More

What Does The Blue Spares Service Provide?

When you rely on machines for your business to operate, break-downs bring everything to a...

Find Out More

Blue Supply New £5 Million Recycling Plant

The MP for Leamington Spa and Warwick, Matt Western has formally opened Fortress Waste’s new...

Find Out More

Which Everyday Products Can Be Recycled?

In the U.K we buy around 3.7 million tonnes of plastic products each and every year. With only...

Find Out More

Finding the right recycling system

Every recycling operation in the UK would likely benefit from its own custom made plant...

Find Out More

J. Davidson take on the MHL350F

Long-standing Fuchs customer J. Davidson Scrap Ltd have recently taken delivery of a new MHL350F to...

Find Out More

A Discussion on Recycling

Every day we are told how important it is to recycle. From magazine articles to televised...

Find Out More

Enterprise Skiphire installs tailor-made BlueMAC recycling plant

Enterprise Skiphire has recently invested in an extremely innovative, custom made recycling plant...

Find Out More

Blue Group Announces Distribution Agreement with Major Wire

Blue Group are delighted to announce an exclusive distribution agreement with Canadian Company,...

Find Out More

Another Mobile Screen for longstanding customer JPE Aggregates

JPE Aggregates is a midland based aggregate supplier specialising in the delivery of sand, recycled...

Find Out More

Creeton take the new Chieftain 2200

Following the purchase of a new Premiertrak 400 XA Jaw crusher in 2017, Creeton Quarry have...

Find Out More

Westminster Waste invest in electric

For wood waste processing, the benefits over diesel can be substantial in certain...

Find Out More

Blue Group Appoint Michael Strain

Due to strong recent growth, plant design and build specialist BlueMAC, has announced the...

Find Out More

FDS Grab Hire purchase Warrior 1400X from Blue

The origins of FDS began in 2001, when business owner Franco De Simone set up FDS Building...

Find Out More

Why you should be using Taurus Bluline Shear Balers

The Taurus Bluline shear balers from Blue Group are a hugely versatile machine capable of pressing...

Find Out More

Tudor Griffiths invests in Fuchs for their recycling site in Ellesmere.

The new Fuchs MHL331 F series is the latest acquisition by the TG Enviro division, which is...

Find Out More

I. J. Kayes Scrap Metal Ltd. are blown away by the performance of The Fuchs’ MHL360 F

Due to increased tonnages coming in to site, and a soon to arrive new shear baler with increased...

Find Out More

Bendall’s Metal Recycling in Gloucester takes on its second Fuchs MHL350 in less than a year

Family owned Bendall’s Metal Recycling Ltd have recently purchased their second Fuchs MHL350...

Find Out More

Restructuring at Blue Group

At Blue Group, we have enjoyed a significant period of success over a prolonged number of years,...

Find Out More

Jones Skip Hire purchase Fuchs MHL350

Blue Southern have recently delivered a Fuchs MHL350 to Jones Skip Hire. The Wolverhampton based...

Find Out More

Crow Metals purchases second Fuchs Material Handler

Crow Metals, is a 4th generation family business, which was originally set up by W. Wakefield in...

Find Out More

The Terex Brand: Powerscreen and EvoQuip

Blue Group is one of the UK’s biggest dealers for the Terex crushing and screening brands. The...

Find Out More

Quality Freight UK invests £700,000 in new fuchs crane

Quality Freight UK has significantly increased its cranage capability at its Ellesmere Port main...

Find Out More

MHL390 F with New Fuchs® Cabin, Wins Prestigious Design Award

The MHL390 F with new Fuchs® cabin, won the prestigious iF Design this year. Germany’s oldest...

Find Out More

What Happens To Our Waste When We Throw It Away?

After throwing your rubbish into the bin and having it collected we don’t tend to give much...

Find Out More

Blue Fuchs increase focus on Scottish market

Blue Fuchs, which has its head office in Portishead near Bristol, is increasing its focus on the...

Find Out More

Blue Fuchs hit the target for Top Gear.

Blue Fuchs, a division of Blue Group, were recently on the receiving end of an unusual request from...

Find Out More

Boden Group Purchase Doppstadt High Speed Shredder

One of the UK’s biggest and most established wood waste recyclers, The Boden Group, have recently...

Find Out More

Let’s Talk About Wood Shredders

At Blue Group we pride ourselves on our vast range of material processing equipment, which is...

Find Out More

Wood Shredders and Chippers: Economical Applications

In the recycling industry companies are always looking for ways to recycle more. With the demand...

Find Out More

WSR Recycling’s Doppstadt 3060K processes an epic 100 tonnes per hour

WSR Recycling have upgraded to a Doppstadt DW 3060K BioPower Shredder following expansion at their...

Find Out More

Blue is a one stop shop for Prichard’s Contracting

Prichard’s Contracting takes advantage of being able to purchase all their wood recycling...

Find Out More

Derby Crushing and Screening purchase the impressive EvoQuip Cobra 230 Impactor.

Derby Crushing and Screening have purchased an EvoQuip Cobra 230 Impactor crusher from Blue to...

Find Out More

EvoQuip Cobra 230 The perfect solution for Cornish Roads

Mark Coad purchases the first EvoQuip Cobra 230 impact crusher in the Southwest of England supplied...

Find Out More

The Metrotrak doubles production rate for Dolan Skips

Dolan Skip Hire was established by Kieran Dolan and his wife Theresa Dolan in 2007. Over the years...

Find Out More

When there’s no space for a full-size crusher, a Hartl HBC 950 Crusher Bucket is just the job for JPE Aggregates.

JPE is one of the Midlands leading suppliers of aggregates, sand and soils to the construction...

Find Out More

New Powerscreen Metrotrak for Lanz Group

Leading Waste Management Company Lanz Group, who have various sites in Berkshire as well as two in...

Find Out More

Three Major Scottish Customers Choose Powerscreen for the First Time

Grange Quarry, Barrachander Quarry and Miller Plant have recently chosen Powerscreen equipment for...

Find Out More

Cone Crusher Applications

You will usually find cone crushers in a number of industries that revolve around mining,...

Find Out More

The Metrotrak HA Jaw Crusher by Powerscreen

The Powerscreen crusher range from Terex including; mobile jaw crushers, cone crushers and impact...

Find Out More

The Machinery Debate: New or Used

The discussion that depicts second hand items and brand new items against one another can be...

Find Out More

Crusher Types

Blue Group supply world leading materials processing equipment for a wide variety of different...

Find Out More

Blue Central Expand Powerscreen Territory

With over 50 years powering the industry, Powerscreen has developed and maintained an aggressive...

Find Out More

Powerscreen Premiertrak R400 and Warrior 1400X assist with £192 million bypass

The Premiertrak R400 mobile jaw crusher and Warrior 1400X mobile screen were cleaning up the...

Find Out More

Blue to attend Demolition Expo 2017

Blue are delighted to be attending Demolition’s biggest event on 22nd - 24th June at Herts...

Find Out More

Crushintons Ltd take first ever EvoQuip machine in the South East

Crushintons Ltd, based in Kent have recently purchased a new Bison 120 Jaw Crusher from Blue...

Find Out More

Leiths Take Second Aggresand 165 Wash Plant from Blue Scotland

The Leiths Group, a multi-discipline organisation and one of Scotland’s largest, privately owned...

Find Out More

Blue Central to Exhibit at Lamma 2017

Blue Machinery Central will be exhibiting at the Lamma event The event is to take place on...

Find Out More

Britaniacrest Recycling Goes Blue Again with Mobile Jaw Crusher

Britaniacrest Recycling Ltd, a family business formed in 1993 by Ray Foss Snr and with three sites...

Find Out More

Leiths take delivery of seven Powerscreen Mobile Crushing and Screening Plants

Leiths (Scotland) Ltd, a multi-discipline organisation and one of Scotland’s largest, privately...

Find Out More

Blue handed RoSPA 2019 Silver Award

Blue Machinery (Group) Ltd has achieved a Silver in the internationally-renowned RoSPA Health and...

Find Out More

Blue Spares invest to further strengthen customer support

As part of the ongoing investment in our Group infrastructure, Blue Spares has recently gone...

Find Out More

Blue Group demonstrate a range of new equipment at Open Day

Blue Group recently held a highly successful open day The event was held over two days in July,...

Find Out More

Blue Ireland to exhibit at CQMS

Blue Machinery Ireland, part of Blue Group will be exhibiting at this year’s CQMS. The business...

Find Out More

Blue Scotland Announce Open Day

Blue Scotland will be holding a Waste Recycling Open Day on Thursday May 11th and Friday May 12th...

Find Out More

RWM a huge success for Blue Group

Since Blue Group was formed eleven years ago, the company has always been a major exhibitor at the...

Find Out MoreBlue Group Become UK Distributor for Fortress Shears

Following on from their recent acquisition of Murray Plant, Blue Group have announced an agreement...

Find Out More

D Wardle (Plant) Ltd Purchase Rammer’s Latest and Biggest Hammer.

Murray Plant have recently delivered a 9033 hydraulic Rammer Hammer to D Wardle (Plant) Ltd. The 7...

Find Out More

Blue Purchase Murray Plant

Blue Group have announced the purchase of Murray Plant, the Rammer distributor for the...

Find Out More

Blue to Exhibit at the Organics Conference

Blue are delighted to be exhibiting at Organics Recycling 2017 which is to be held at JCB,...

Find Out More

KJ Crushing Ltd. take 9th Powerscreen

KJ Services located in South Wales have ordered a further three Powerscreen machines, following the...

Find Out More

BlueMAC Awarded for its Manufacturing Innovation

BlueMAC Manufacturing has been rewarded at the annual Sustainable Ireland Awards for innovation in...

Find Out More

Central create Christmas cheer

Blue Central have donated over £2,000 worth of toys and gifts to a local charity, in preference to...

Find Out More

Falkirk Council are leading the way with a BlueMAC waste recycling plant

The aim is to recycle over 70% of the collected household material, with a maximum of just 5% going...

Find Out More

Ireland’s First Electric Fuchs Materials Handler Goes To RiverRidge Recycling

RiverRidge Recycling has just taken delivery of Ireland’s very first electrically powered Fuchs...

Find Out More

Furnishing Frimstone

Frimstone Limited, which has 13 sites throughout East Anglia recently approached Blue Central to...

Find Out More

George Beattie and Sons Ltd choose an R400 mobile jaw crusher

Blue Machinery Scotland has delivered a Powerscreen Premiertrak R400 Pre Screen mobile jaw crusher...

Find Out More

Blue Fuchs Supply Quality Freight UK With Two New Fuchs Material Handlers

Blue Machinery Fuchs have recently sold two new material handlers to Quality Freight UK as the...

Find Out More

Blue to Supply EvoQuip throughout the UK

Blue have become the exclusive supplier for EvoQuip. This new range from Terex offers a...

Find Out More

Blue Group Announce Exclusive UK Agreement with Westeria

Blue Group are delighted to announce that an exclusive distribution agreement for the UK and...

Find Out More

The New DW 3060 F Type Waste and Wood Shredder from Doppstadt

The new Doppstadt slow speed waste and wood shredder with innovative shredding system Doppstadt...

Find Out More

Blue Ireland Sponsor Prestigious Killeen G.C. Pro-Am

Blue Machinery Ireland have been confirmed as the new headline sponsor for prestigious Killeen...

Find Out More

New Fines Clean Up Plant at Lowmac

Lowmac Waste & Recycling has invested in an extremely versatile, tailor-made recycling plant to...

Find Out More

Scotland Makes its Move

Blue Scotland has recently moved to a 3.5 acre facility, incorporating newly renovated office...

Find Out More

Two PT R400 Mobile Jaw Crushers bought to crush foundations

ADM Regeneration based in Lymm, was formed in 2011 by current owner Adam Matthews, undertaking...

Find Out More

BlueMAC Spreads Its Wings!

BlueMAC is now pleased to announce that it has appointed SKALA Australasia Pty Ltd as the exclusive...

Find Out More

The Quest for Zero to Landfill

Blackpole Recycling, based in Worcester, have recently purchased a Fuchs MHL 250 and a Doppstadt...

Find Out More

New Modular Wash Plant for Breedon Aggregates

Breedon Aggregates has installed a Terex® Aggresand 165 Wash Plant at their Capo Quarry, Edzell,...

Find Out More

Probably the World’s Largest Mobile Trommel Goes to Gallagher Aggregates

Following an extensive and successful demonstration at Gallagher Aggregates’ Hermitage Quarry,...

Find Out More

BlueMAC All Metal Separator

Available in tracked, static or skid variations. Boost your profit with contamination free...

Find Out More

Doppstadt Launch AK560 waste and wood shredder

Due to the exceptionally high demand for the Doppstadt AK 510 shredder over the last few years, the...

Find Out More

The New SM 620 SA mobile trommel screen available from January 2016

Testing of the new SM 620 SA mobile trommel screen prototype has now been completed meaning that...

Find Out More

Incredible year for Blue Group

Blue Group have had an amazing year. Starting with new offices opening in Portishead, near Bristol,...

Find Out More

Blue Group and ZenRobotics announce distribution agreement for the UK

Blue Group are delighted to announce that a distribution agreement for the UK and Ireland has been...

Find Out More

Biggest Ever Plant for BlueMAC Designed and built for Irish Waste in Carryduff, Belfast

BlueMAC’s largest plant to date, designed and built for Irish Waste, has recently started to...

Find Out More

Scaling it up at the London Lord Mayor’s Show.

A rainy 14th November 2015 saw Blue taking part in the 800th London Lord Mayor’s Show, with the...

Find Out More

O’Donovan’s take 3 of the best from Blue London

O’Donovan Waste Disposal Limited is one of London’s leading independent waste management and...

Find Out More

Blue Group at Lord Mayors Show 2015

The Blue Group are taking part in this year’s London Lord Mayor’s Show procession which takes...

Find Out More

Blue Steals the Show at RWM

Blue again wowed visitors at this year’s RWM exhibition held at the NEC in Birmingham. The 430sqm...

Find Out More

Premiertrak 600 Mobile Jaw Crusher

Malcolm Construction take delivery of the new Powerscreen Premiertrak 600 Mobile Jaw...

Find Out More

Danny Morgan becomes part of the Blue Team

Blue Group are delighted to announce the appointment of Danny Morgan as Export Sales...

Find Out More

Tony Weir joins Blue as Technical Director

With his 25 years’ experience in the crushing and screening industry, along with a certified...

Find Out More

Blue at RWM Exhibition – 15th – 17th September 2015

Blue will again be exhibiting at this year’s RWM exhibition, which is to take place between...

Find Out More

Doppstadt Expo

Doppstadt recently celebrated their 50th Anniversary with an incredible EXPO, attracting over 3,000...

Find Out More

John Wade Celebrates 50 Years in Business

Longstanding Blue Scotland customer, John Wade Group recently celebrated their 50th anniversary at...

Find Out More

New offices for Blue Southern and Blue Fuchs

An £800,000 refurbishment of both the Blue Fuchs and Blue Southern offices in Portishead has...

Find Out More

BlueMAC MRF Installed for Murray Browns

Murray Browns is an independent, family-owned company headquartered in Flixton, near Scarborough,...

Find Out More

High Speed upgrade for McKenzie

Prominent Scottish wood recyclers, M Mckenzie Old Pentland LLP have recently taken delivery of...

Find Out More

Blue Machinery Scotland Named “World Dealer of the Year” at Powerscreen World Dealer Conference

Blue Machinery (Scotland) Limited is proud to announce that the company has received the highest...

Find Out More

Blue Southern support NICU Charity

Blue Group are delighted to support NICU, a charity that is close to all our hearts. Blood Bikes...

Find Out More

Season’s Greetings from Blue

The team at Blue Group would like to wish you a very Merry Christmas and a healthy, happy,...

Find Out More

Tamar Organics Takes Delivery of Two More Doppstadt Machines

Tamar Organics has purchased a Doppstadt DW 3060K Bio Power shredder and a Doppstadt SM 620K...

Find Out More

Transwaste score in Blue Spares Promotion

Bruce Pritchard of Transwaste Recycling and Aggregates was the lucky winner of Blue Spares latest...

Find Out More

ABP Teignmouth add to Fuchs fleet

Blue Fuchs have once again supplied a Fuchs material handler to the UK's leading ports group,...

Find Out More

Blue Spares show their true colours

Lots of companies talk the talk but do they actually walk the walk? Blue Spares has introduced its...

Find Out More

BlueMAC Achieves ISO Quality Management Accreditations

Specialist bespoke recycling plant manufacturer, BlueMAC, has achieved two stringent ISO quality...

Find Out More

Thompsons Plant Hire Continues Allegiance to Blue Machinery

Thompsons Plant Hire, of Maryport, Cumbria, has purchased another Doppstadt machine from Blue...

Find Out More

Hugely successful Scot Plant for Blue Scotland

Blue Scotland are delighted to announce another hugely successful Scot Plant exhibition. The...

Find Out More

Port of Workington takes Specialist Fuchs Materials Handler

One of the UK’s fastest growing ports, the Port of Workington in West Cumbria, has further...

Find Out More

New fleet of vehicles for Blue Fuchs

After another successful year as an accredited Terex Fuchs Three Crown distributor, Blue Machinery...

Find Out More

ReFood install two Tigers in Widnes

Blue Machinery (Central) are fortunate to be part of the most exciting Biogas Plant the UK Waste...

Find Out More

R.Collard Limited installs bespoke MRF from BlueMAC

Leading manufacturing company BlueMAC has designed and built another tailor-made installation; this...

Find Out More

Have you got your Winter Blues?

Keep yourself warm this Winter with Blue Spares. For a limited time only, all orders placed over...

Find Out More