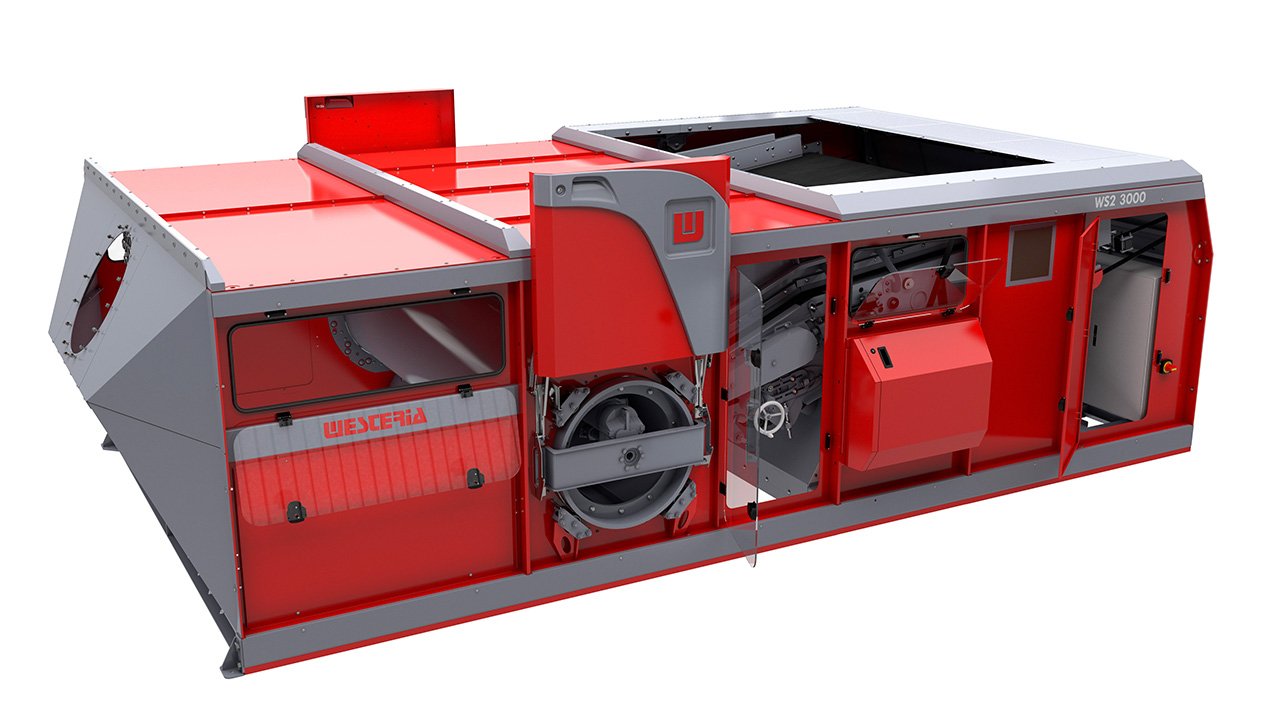

WESTERIA® WINDSHIFTER AirStar®

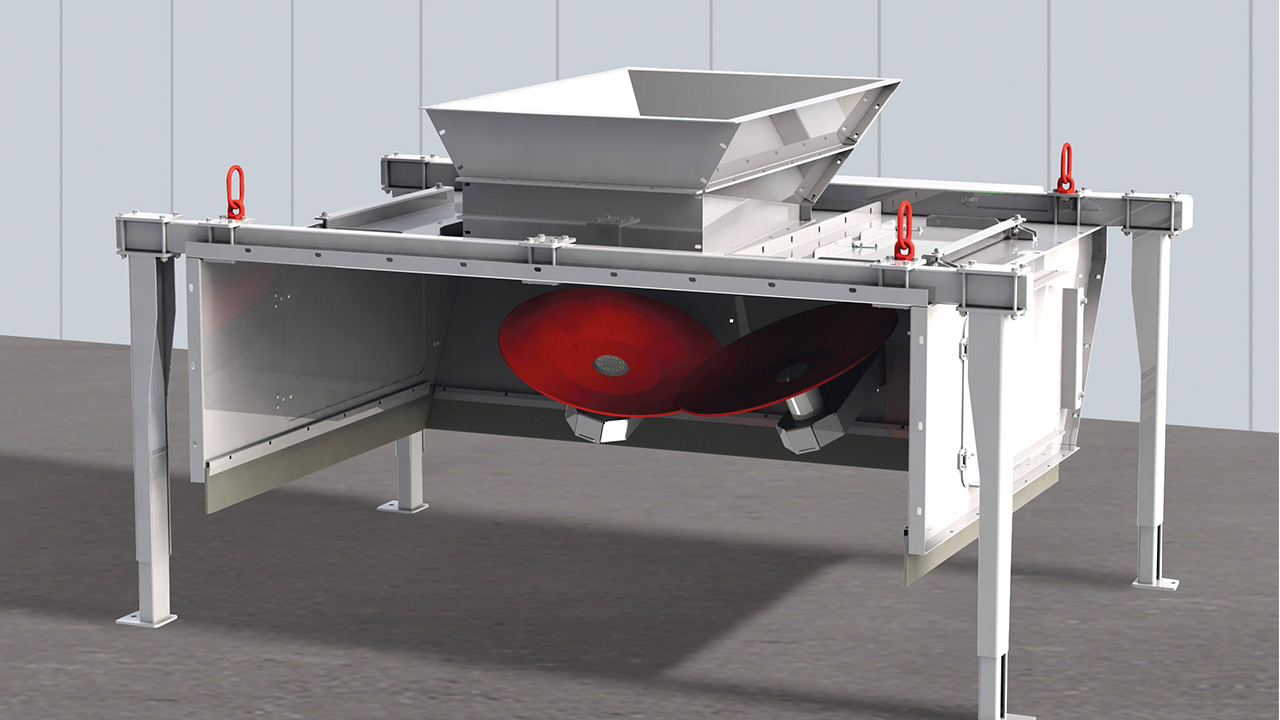

Globally renowned for cutting edge windshifting technology, the German built Westeria truly take it to another level. The Westeria windsifter technologies are designed to be rugged, powerful and energy efficient. A proven method to separate heavy and light fractions is what differentiates the patented Westeria® windsifter. The materials are separated by a process that involves three main components. Theses are the acceleration belt, the air jet and separation drum.

For optimal results the accelerator belt gives a single-layer distribution of the input material. This even spread across the width of the windsifter is critical. Here the material is accelerated to an adapted speed then transported to the ejection edge. Then the materials falling from above get into an upward current that is generated through an adjustable air jet underneath the feeding belt.

Additionally the air stream meets the upper area of the rotation drum in the windsifter and is fed through it into the expansion chamber with the laminar flow. The material in the windsifter meets the air flow and is separated into light and heavy materials.

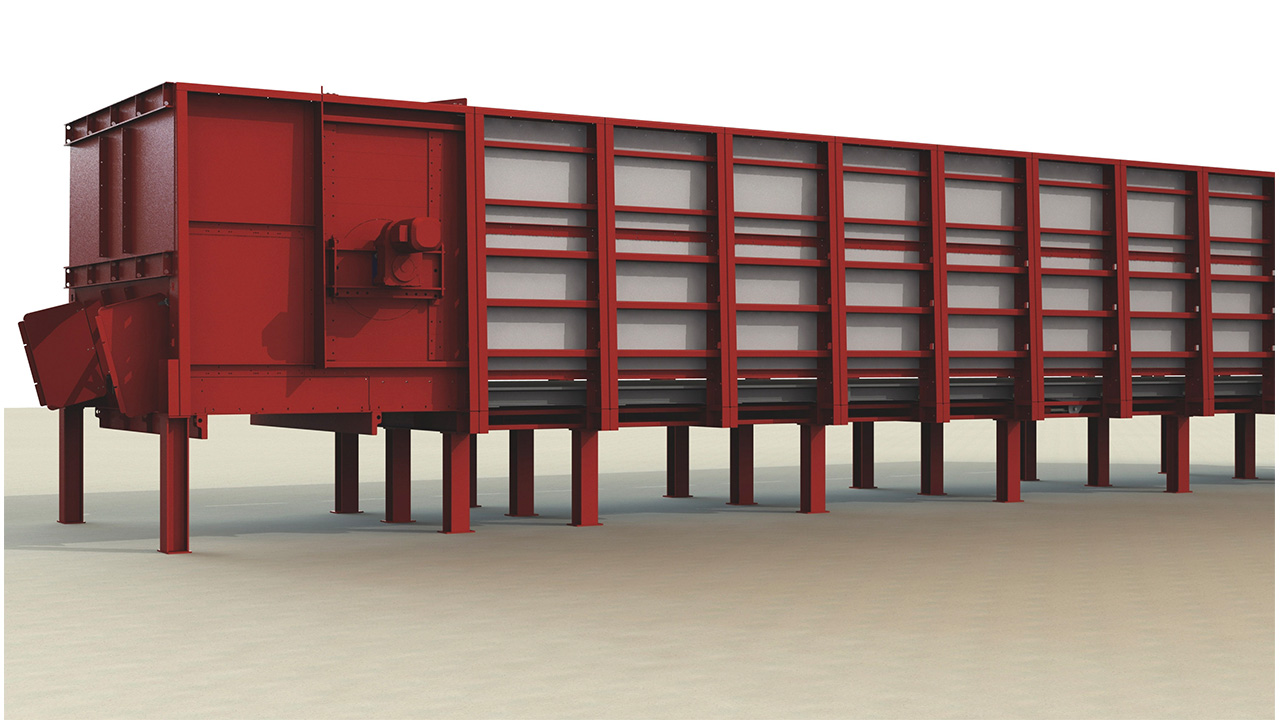

The light materials are transported with an air flow with high speed into the expansion chamber, where the air speed is reduced so much that the light materials reach a container or a discharge belt. The heavy materials fall down from the rotation drum in the windsifter into a container or onto a discharge belt.

The air volume brought into the expansion chamber is removed again in the upper section of the windsifter and, depending on the individual application, is once more drawn in by the blower or routed into a filter system. To retain high-grade recycling raw materials, Westeria® has designed a special windsifter to unerringly sort the input material into three fractions with a high degree of selectivity.